VISION

PRODUCTS

TWIN SCREW EXTRUDERS

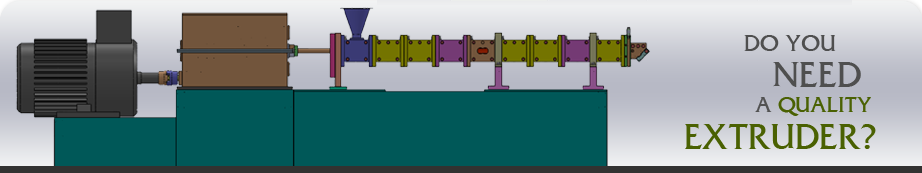

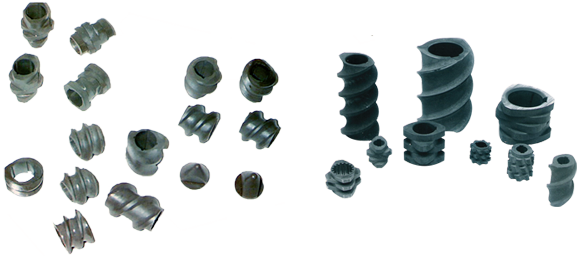

TWIN SCREW SHAFT

- Co-rotating - intermeshing

- Dispersion by kneading

- Helical path mixing

- Reverse Element

- Left and Blister action

Control Panel

In all our extruders AC Inverters with good PID controllers. SSR Controled CSATING Headers and Barrel Cooling by AIR & Water or Stream.

SEGEMENTED SINGLE SCREW EXTRUDER WITH VENT AND SIDE FEEDER

OUR PRODUCT LINE

- Twin Screw Extruder ( Model:FUE)

- Segmented single Screw extruder(Model: FKE)

- Side Feeder( Twin Screw)

- Vertical Feeder

- Air Knife

- Pelletizer

- Vaccum Degassing System

- Liquid Injection System

- Volumetric Feeder ( Single & Twin Type)

- Loss-in-Weight Feeder ( Single & Twin Type)

- Spare Screw Elements and Barrels

- Hydraulic Screen Changer

Design with Manufacture and Delived to the customer with high quality with energy saving.

Extrusion plants which are capable processing any Polymers with any Filler with low maintenance cost.

Design with Manufacture and Delived to the customer with high quality with energy saving.

Extrusion plants which are capable processing any Polymers with any Filler with low maintenance cost.